Ice dams and gutter icing formed by melting snow on roofs are “invisible killers” that threaten the safety of buildings in severely cold winter areas. Ice clogs the drainage system, leading to water backup, roof leakage and even structural damage, while the traditional manual shoveling or chemical snowmelt is not only inefficient, but also may corrode the gutter and pollute the environment. The gutter

china snow melting mat system has become one of the core technologies for modern buildings to resist snow and ice disasters by virtue of its precise temperature control, intelligent operation and long-life characteristics. The heating cable snow melting system actively raises the roof temperature through the conversion of electrical energy into thermal energy, melting snow or preventing ice formation. Its core consists of high-temperature-resistant and anti-aging alloy resistance wire, and the outer layer is wrapped with insulation, shielding and waterproof sheath to ensure stable operation in humid and low-temperature environments. The system monitors environmental changes in real time through temperature and humidity sensors or intelligent controllers, and automatically starts and stops heating, realizing precise temperature control and energy-saving operation.

First, the gutter

china snow melting mat system solutions

Gutter as a roof drainage “throat”, its narrow structure and exposure to the environment makes it easier to ice:

Ice dam formation: after the roof snow melts, the water flows to the low-temperature gutter when refreezing, blocking the drainage channel.

Freeze damage: Ice expansion squeezes gutter joints, causing deformation of the metal or cracking of the PVC material.

Drainage failure: After freezing, rainwater cannot be discharged, backing up and eroding the waterproof layer of the roof, triggering leakage.

Targeted solutions for heating cable systems:

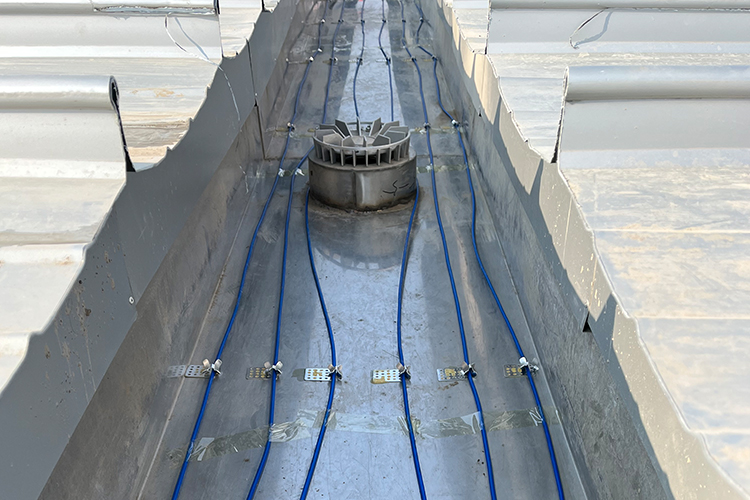

Precise deployment: laid along the bottom of the gutter, the inner wall of the downpipe and the edge, directly heating the key areas.

Gradient temperature control: Adjust the power according to the temperature difference between different sections of the gutter to avoid localized overheating or insufficient snow melting.

Waterproof and anti-corrosion: adopting double-layer fluorine plastic sheath and 316 stainless steel braided layer, adapting to the harsh environment such as humidity and salt spray.

Second, the advantages of gutter

china snow melting mat

Active defense against ice dams: avoid water leakage from the root cause and reduce roof maintenance costs by more than 80%.

Intelligent energy-saving operation: compared to the traditional solution of continuous heating, self-regulating cables can save 40%-60% energy.

Protection of the building structure: Eliminates physical damage to gutter materials caused by freezing and expansion, extending service life by 2-3 times.

Zero environmental burden: Replaces salt-based snowmelt, avoiding corrosion of metal guttering and contamination of soil and water bodies.

Initial investment: heating cable system about 20,000-30,000 RMB (including installation).

Annual maintenance cost: almost zero, much lower than the average annual expenditure of more than 5,000 yuan for manual snow removal.

Cycle time: 3-5 years to recover costs by reducing maintenance costs

Gutter snow melting

China heating cable is not only a technical product, but also an upgrade of building safety thinking. It redefines the standard of winter drainage management by replacing “after-the-fact remediation” with “preventive maintenance”. With the improvement of green building regulations and the popularization of intelligent hardware, this technology is penetrating from high-end commercial buildings to schools, communities, and rural homes, and becoming a “life-saving project” for buildings in cold regions. In the future, with the breakthroughs in material science and IoT technology, the gutter snow-melting system will be smarter and lower-carbon, creating a safe winter environment that harmonizes with nature for human beings.