In the installation and maintenance of electric heating cables, end sealing is a frequently overlooked yet critically important step. Many dismiss it as an insignificant “little tail,” unaware that this minor oversight can compromise the stable operation of the entire system and even create safety hazards. Next, we'll delve into why proper end sealing is so crucial. In the long run, this seemingly small action forms the essential foundation for the system's enduring and safe operation.

The primary reason lies in waterproofing and moisture resistance. Whether in outdoor pipelines, underground facilities, or industrial environments with condensation, moisture is ever-present. If the end of an electric heating cable is not sealed, moisture can easily seep in through gaps in the wiring. This not only reduces insulation strength and increases the risk of leakage but may also corrode internal metal components, accelerating product aging and significantly shortening its service life.

Secondly, it ensures heating efficiency. The core function of electric heating cables is to precisely supplement heat. If the end is not properly sealed, heat will dissipate through the opening. This can not only lead to insufficient local temperatures in the pipeline, affecting the normal flow of the medium (such as crude oil solidification or chemical solution crystallization), but also force the system to operate at higher power, resulting in additional energy consumption.

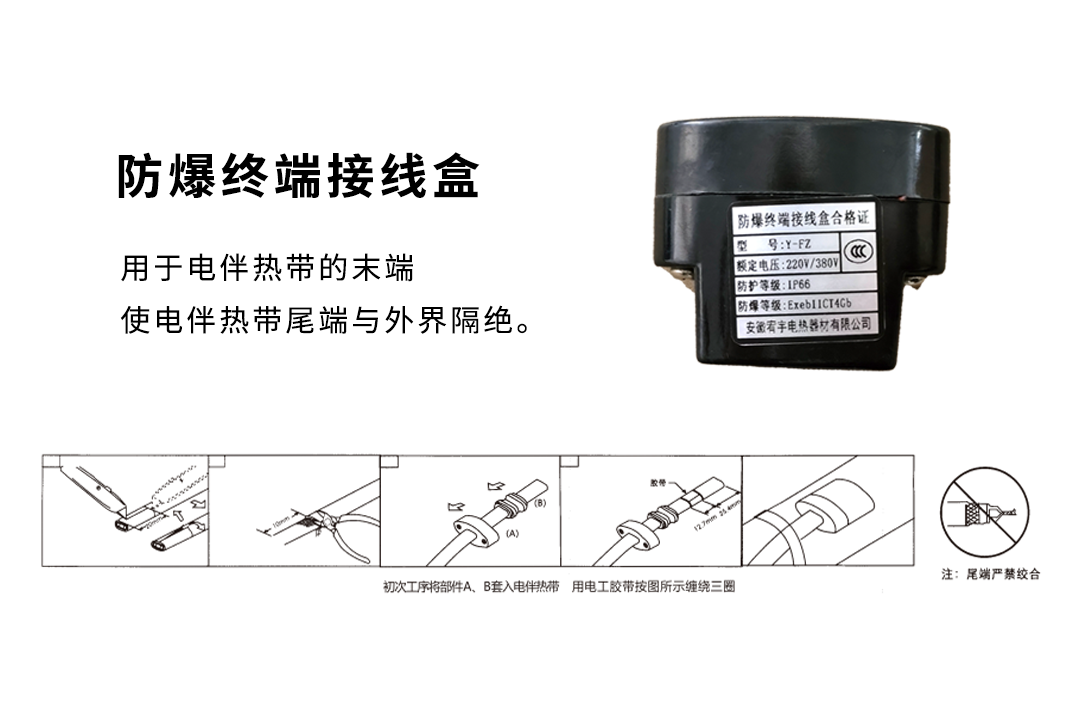

Safety and explosion protection are particularly critical. In flammable and explosive environments like petrochemical plants and hazardous material storage facilities, an unsealed end is a potential hazard source. Combustible gases may infiltrate the interior, and if exposed to electrical sparks or localized overheating generated during heating operation, it could easily trigger a flash fire. Proper sealing effectively isolates hazardous media, establishing a robust barrier for safe production.

Furthermore, proper sealing prevents the ingress of foreign substances like dust and corrosive particles, avoiding interference with the electrical performance of the heating cable. Achieving reliable sealing is straightforward: selecting professional end terminal boxes and adhering strictly to installation standards ensures long-term protection.

Details determine system reliability. The stable operation of an electric heating system depends on meticulous attention to every detail. Prioritizing end sealing represents a significant investment in the overall safety and energy efficiency of the system.

In the field of electric trace heating cable, professional execution often lies in the details. Only by maintaining a rigorous approach at every stage can we truly achieve stable, efficient heating protection, ensuring warmth and safety accompany every section of piping.